Change 1 2-739

TM 9-2320-365-20-1

CAUTION

Use care when testing electrical connectors.

Do not damage connector pins or sockets

with multimeter probes. Failure to comply

may result in damage to equipment.

NOTE

Inspect connector pins/sockets for damage,

corrosion, and serviceability. Check that

connector pins are not pushed back and

are capable of making good contact.

CONTINUITY TEST

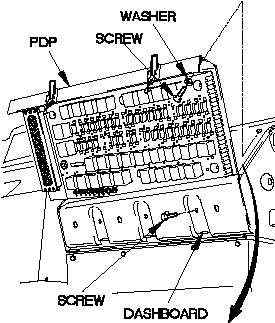

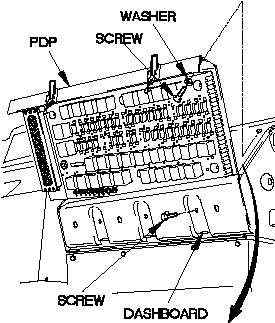

(1) Remove PDP cover (para 16-2).

(2) Remove three screws and washers from

PDP.

(3) Remove three screws from PDP.

(4) Lift PDP outward to gain access.

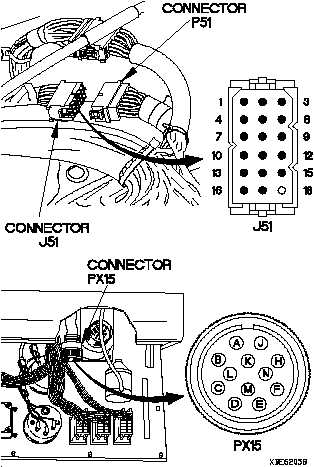

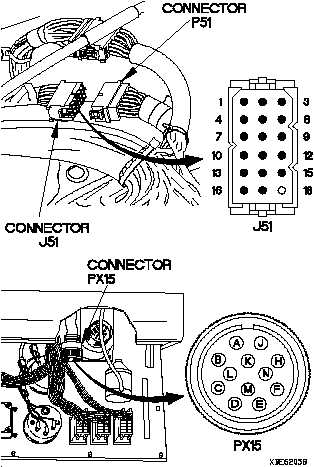

(5) Disconnect connector J51 from connector

P51.

(6) Set multimeter to ohms.

(7) Connect positive (+) probe of multimeter

to connector PX15 socket N.

(8) Connect negative (-) probe of multimeter

to connector J51 pin 6 and note reading

on multimeter.

(9) If continuity is not present, repair wire 23

from connector PX15 socket N to

connector J51 pin 6 (para 2-40) or replace

WTEC II dashboard cable assembly (para

7-10) or WTEC III dashboard cable

assembly (para 7-11).

(10) If continuity is present, repair wire 23

from connector P51socket 6 to splice E18

(para 2-40) or replace rear lights cable

assembly (para 7-75).

(11) Connect connector PX15 to main light

switch.

(12) Install instrument panel assembly

(para 7-15).

(13) Connect connector J51 to connector P51.

(14) Install PDP on dashboard with three

screws.

(15) Install three washers and screws in PDP.

(16) Install PDP cover (para 16-2).