Inspect connector pins/sockets for damage,

corrosion, and serviceability. Check that

connector pins are not pushed back and

are capable of making good contact.

NOTE

CAUTION

Change 1 2-1513

TM 9-2320-365-20-2

Use care when testing electrical connectors not

to bend connector pins or damage connector

sockets with multimeter probes. Failure to

comply may result in damage to equipment.

CONTINUITY TEST

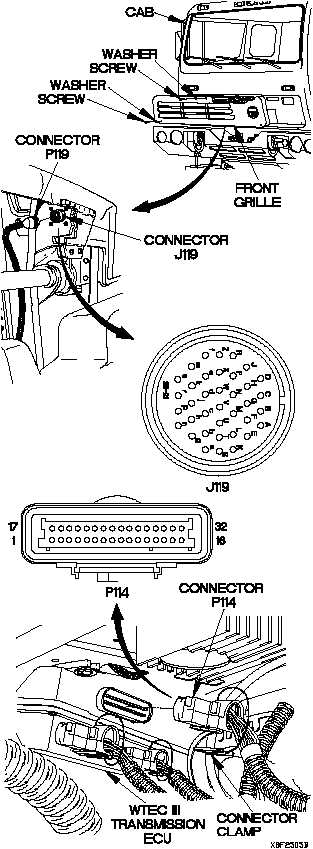

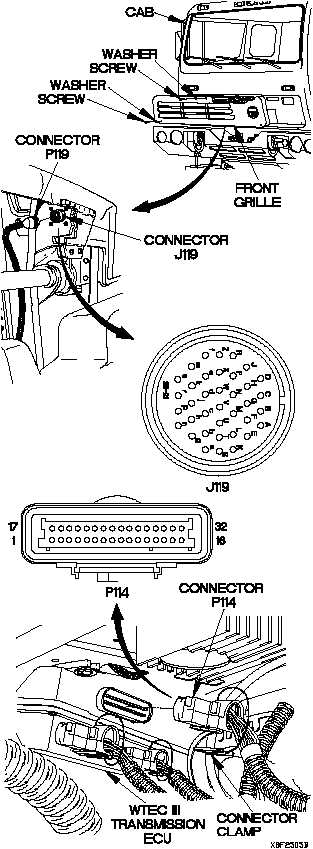

(1) Remove two screws and washers from

front grille.

(2) Remove screw and washer from front

grille.

(3) Remove front grille from cab.

(4) Disconnect connector P119 from

connector J119.

(5) Remove kick panel (para 16-3).

(6) Disconnect connector clamp from

connector P114.

(7) Disconnect connector P114 from WTEC III

transmission ECU.

(8) Install jumper wire from connector J119d

to connector J119a.

(9) Set multimeter to ohms.

(10) Connect positive (+) probe of multimeter

to P114-27.

(11) Connect negative (-) probe of multimeter to

connector P114-25 and note reading on

multimeter.

(12) Connect negative (-) probe of multimeter to

all other sockets in connector P114, one at

a time, and note reading on multimeter.

(13) Connect negative (-) probe of multimeter to

ground and note reading on multimeter.

(14) Connect positive (+) probe of multimeter

to connector P114-25.

(15) Connect negative (-) probe of multimeter to

all sockets in connector P114 (except

P114-27), one at a time, and note reading

on multimeter.

(16) Connect negative (-) probe of multimeter to

ground and note reading on multimeter.

(17) If continuity is not present in step 11, or

continuity is present in step 12, 13, 15, or

16, replace WTEC III cab transmission

harness (para 7-86).

(18) Remove jumper wire from connector J119.

(19) Connect connector P114 to WTEC III

transmission ECU.

(20) Connect connector clamp on connector

P114.

(21) Install kick panel (para 16-3).