TM 9-2320-365-20-3

8-14. TRANSMISSION OIL COOLER HOSES INITIAL INSTALLATION

This task covers:

a. Installation

b. Follow-On Maintenance

INITIAL SETUP

Equipment Conditions

Engine shut down (TM 9-2320-365-10).

Cab raised (TM 9-2320-365-10).

Transmission oil cooler tubes removed (para 8-11).

Tools and Special Tools

Goggles, Industrial (Item 15, Appendix C)

Tool Kit, Genl Mech (Item 44, Appendix C)

Pan, Drain (Item 24, Appendix C)

Crowfoot Attachment, Socket Wrench (Item 12.1,

Appendix B)

Wrench, Torque, 0-600 lb-ft (Item 59, Appendix C)

Socket Set, Socket Wrench (Item 34, Appendix C)

Wrench, Torque, 0-200 lb-in. (Item 58, Appendix C)

Materials/Parts

Ties, Cable, Plastic (Item 69, Appendix D)

Dispenser, Pressure Sensitive Adhesive Tape (Item

21, Appendix D)

Materials/Parts (Cont)

Antiseize Compound (Item 63, Appendix D)

Hose Assembly, Nonmetallic (Item 25.2, Appendix

D)

Hose Assembly, Nonmetallic (Item 25.3, Appendix

D)

Hose Assembly, Nonmetallic (Item 25.4, Appendix

D)

Elbow, Pipe to Tube (Item 21.2, Appendix D)

Adapter, Straight, Pipe to Boss (2)(Item 1.1,

Appendix D)

Elbow, Pipe to Boss (Item 21.1, Appendix D)

Clamp, Loop (4) (Item 15.1, Appendix D)

Screw, Cap, Hex Hd (4) (Item 56.2, Appendix D)

Nut, Self-Locking (4) (Item 134, Appendix G)

Nut, Self-Locking (4) (Item 145, Appendix G)

Bracket, Angle (Item 14.2, Appendix D)

Screw, Cap, Hex Hd (4) (Item 56.3, Appendix D)

Gasket (Item 40.1, Appendix G)

Personnel Required

(2)

WARNING

• Wear appropriate eye protection when

working under vehicle due to the possibility

of falling debris.

Failure to comply may

result in injury to personnel.

• Ensure exhaust system is cool before

preforming maintenance. Failure to comply

may result in injury to personnel.

a. Installation.

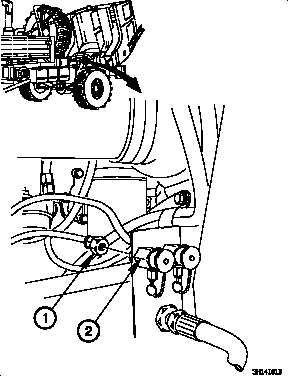

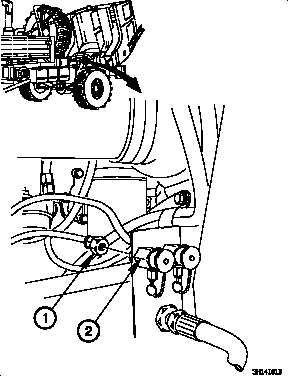

(1) Remove transmission oil sampling hose (1) from

transmission

oil

sampling

valve

(2).

Discard

transmission oil sampling hose.

Change 1

8-55