TM 9-2320-365-20-3

11-23. SERVICE GLADHAND TWO-WAY CHECK VALVE REPLACEMENT

This task covers:

a. Removal

b. Installation

c. Follow-On Maintenance

INITIAL SETUP

Equipment Conditions

Air tanks drained (TM 9-2320-365-10).

Windshield washer reservoir and pump removed (para

18-2).

Cab raised (TM 9-2320-365-10).

Tools and Special Tools

Goggles, Industrial (Item 15, Appendix C)

Tool Kit, Genl Mech (Item 44, Appendix C)

Wrench, Torque, 0-175 lb-ft (Item 57, Appendix C)

Materials/Parts

Dispenser, Pressure Sensitive Adhesive Tape

(Item 21, Appendix D)

Antiseize Compound (Item 63, Appendix D)

Nut, Self-Locking (Item 148, Appendix G)

WARNING

Wear appropriate eye protection when

working under vehicle due to the

possibility of falling debris. Failure to

comply may result in injury to

personnel.

a. Removal.

NOTE

Tag air hoses and connection points prior

to disconnecting.

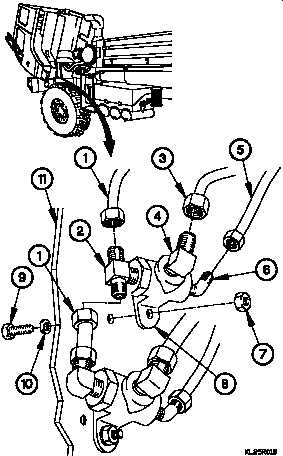

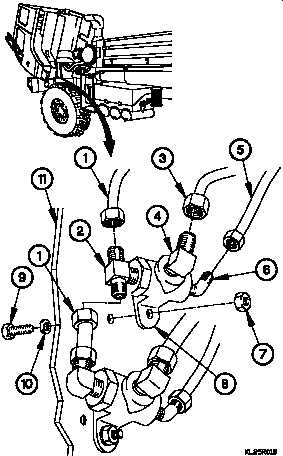

(1) Disconnect two air hoses (1) from branch tee fitting (2).

(2) Disconnect air hose (3) from 90-degree fitting (4).

(3) Disconnect air hose (5) from 45-degree fitting (6).

(4) Remove self-locking nut (7), service gladhand two-way

check valve (8), screw (9), and washer (10) from front

fender (11). Discard self-locking nut.

Change 1

11-123